IndyMill

Jump to navigation

Jump to search

About

Somewhere in 2022 I decided I wanted a CNC machine. I decided to build an IndyMill.

Project website: https://indystry.cc/indymill/

Ordering

TBD

Building

TBD

Setting up GRBL

Installing GRBL

| 🛑 | Dies might be a bad idea, since GRBL has been abandoned since 2019… |

- Install Arduino IDE 1.x (not 2.x!)

- Setup board type

- Setup serial/USB-connection (you might want to add your user to group dialout to allow accessing

/dev/ttyUSB0…) - Download as .zip: https://github.com/gnea/grbl

- Extract zip

- Open Arduino IDE

Sketch →

Library Import as .ZIP → select grbl-master/grbl

File → Examples → grbl → grblUpload

Testing Connection

- Download CNCjs-AppImage: https://cnc.js.org/

- Launch it, set Connection parameters (device / speed)

- Enter something like this:

- Get current settings with

$$

CNCjs 1.10.3 [Grbl]

Connected to /dev/ttyUSB0 with a baud rate of 115200

Grbl 1.1h ['$' for help]

client> $$

$0=10 (Step pulse time, microseconds)

$1=25 (Step idle delay, milliseconds)

$2=0 (Step pulse invert, mask)

$3=0 (Step direction invert, mask)

$4=0 (Invert step enable pin, boolean)

$5=0 (Invert limit pins, boolean)

$6=0 (Invert probe pin, boolean)

$10=1 (Status report options, mask)

$11=0.010 (Junction deviation, millimeters)

$12=0.002 (Arc tolerance, millimeters)

$13=0 (Report in inches, boolean)

$20=0 (Soft limits enable, boolean)

$21=0 (Hard limits enable, boolean)

$22=0 (Homing cycle enable, boolean)

$23=0 (Homing direction invert, mask)

$24=25.000 (Homing locate feed rate, mm/min)

$25=500.000 (Homing search seek rate, mm/min)

$26=250 (Homing switch debounce delay, milliseconds)

$27=1.000 (Homing switch pull-off distance, millimeters)

$30=1000 (Maximum spindle speed, RPM)

$31=0 (Minimum spindle speed, RPM)

$32=0 (Laser-mode enable, boolean)

$100=250.000 (X-axis travel resolution, step/mm)

$101=250.000 (Y-axis travel resolution, step/mm)

$102=250.000 (Z-axis travel resolution, step/mm)

$110=500.000 (X-axis maximum rate, mm/min)

$111=500.000 (Y-axis maximum rate, mm/min)

$112=500.000 (Z-axis maximum rate, mm/min)

$120=10.000 (X-axis acceleration, mm/sec^2)

$121=10.000 (Y-axis acceleration, mm/sec^2)

$122=10.000 (Z-axis acceleration, mm/sec^2)

$130=200.000 (X-axis maximum travel, millimeters)

$131=200.000 (Y-axis maximum travel, millimeters)

$132=200.000 (Z-axis maximum travel, millimeters)

ok

GRBL-Settings

Setting step width

- Change settings as described in Nikodem's manual for stepwidth:

$1=255

ok

$100=640

ok

$101=640

ok

$102=400

ok

$110=1000

ok

$111=1000

ok

$112=1000

ok

$120=80

ok

$121=80

ok

$122=80

ok

I changed above to meet my (micro)-stepping-setup (DIP #2 of my TB6600, micro-step 8, Pulse/Rev 1600) and ball-screws.

$100=320

$101=320

$102=800

Hint: Make sure you reset the machine after changing values, my GRBL acted strangely when not.

Setting directions

Enabling Limit-Switches

- See also:

- Do:

- MAYBE NOT: Enable hard limits:

$21=1 - Enable homing cycle:

$22=1 - Set top left home location:

$23=1(see above links for more values)

- MAYBE NOT: Enable hard limits:

Testing

Try this:

$H

Z-Axis-Probe

- See also:

- Do:

- TBD

Work with CAD- and CAM-Software

Converting STL to solids in FreeCAD

See also: https://forum.freecad.org/viewtopic.php?t=14136

- Open the STL file

- Select object

Part → Create shape from mesh

- Select new object

Part → Converte to solid

Create GCODE with JSCut.org

| 💡 | If you're creating your own SVG, make sure the pockets are "objects", meaning "areas", not paths. |

- Create SVG

- Launch https://jscut.org/

- Open SVG

- Set units correctly (in my case mm)

- Set speeds and diameters, material strength and so on...

- Select object

- Generate operation

- Preview

- Download

- Hope for the best :)

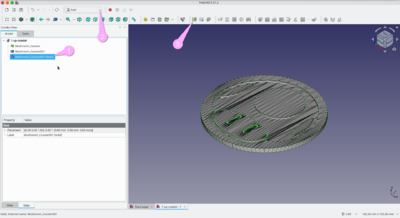

Create GCODE with FreeCAD

See also

Do:

- Launch FreeCAD

- Make sure you have already created proper solids (see above)!

- Make sure units are ok:

Preferences → General → Unit System → Metric small parts & CNC

Output to grbl

- Create tools as needed:

Path → Toolbit Library Editor

- Remove default tool

- Choose Tool, set # to 1

- Set H/V speed

- TBD TBD TBD

Lessons Learned

- Origin is in front-left corner, increasing up (Z), right (X) and back (Y)

- Double-Check all settings before first use (most importantly step width, end switches)

- Don't think it's as easy as 3D-Printing!

- You have to make decisions while creating the GCODE:

- Which pockets should be done first?

- Which pockets should be done last?

- Will any operation make your part move or break?

- Links

- TBD

- Footnotes:

- ↑ https://forum.makerforums.info/t/how-do-i-invert-the-y-and-z-axis-of-my-grbl-cnc-arduino-uno/80114

- ↑ https://www.diymachining.com/downloads/GRBL_Settings_Pocket_Guide_Rev_B.pdf

- ↑ https://linuxcnc.org/docs/html/user/user-concepts.html#_machine_configurations

- ↑ https://www.cnc4fun.com/wp-content/uploads/2019/12/Grbl-Commands-v1.1-2.pdf