CTC Bizer with 0.8mm Nozzle

Jump to navigation

Jump to search

About

A larger nozzle will result in much faster prints, right? Since it affects the printing volume it will affect it like this:

(new diameter / old diameter)³ (0.8/0.4)³ = 8

Hoorray! 8 times faster! At least I thought that…

The Problem

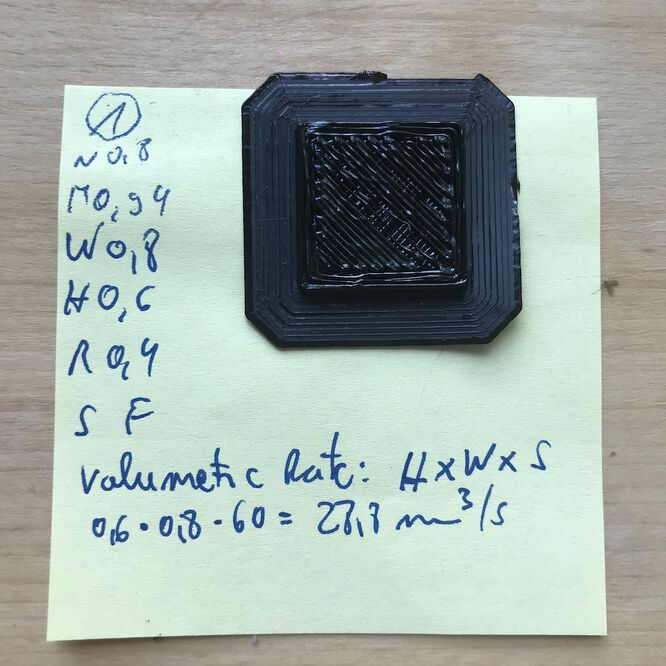

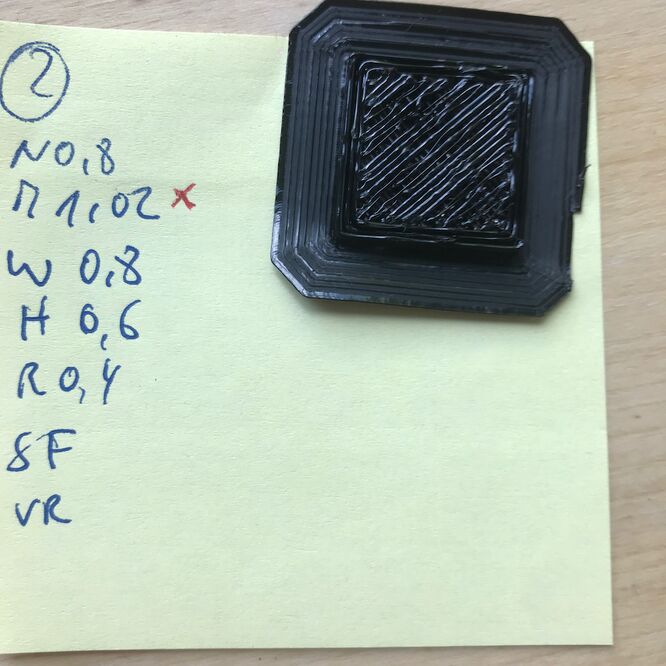

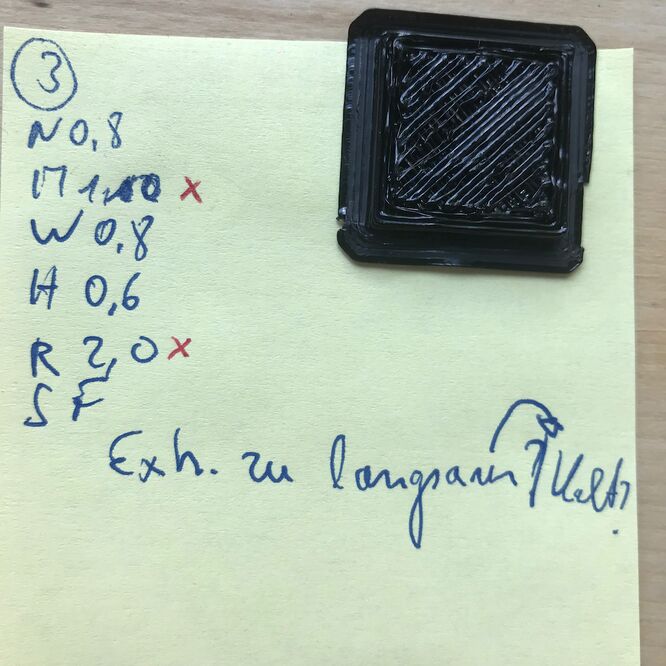

The prints were awful:

- Outer Perimeters looked good, but walls were not completely filled

- Infill looked uneven and had "holes" in it

- Looked like underextrusion, so I cranked up the extrusion multiplier (with no effect)

- Triple-checked that extruder is working and the wires are not (again…) broken

- …read on! The pictures will nicely illustrate what I've changed and what effect it had:

• this was the moment, I remembered that there was a limitation, the volumetric rate, which I had read about some weeks ago on Facebook Simplify3D - Deutschland and Bob's Project Notebook (Muppet Labs)

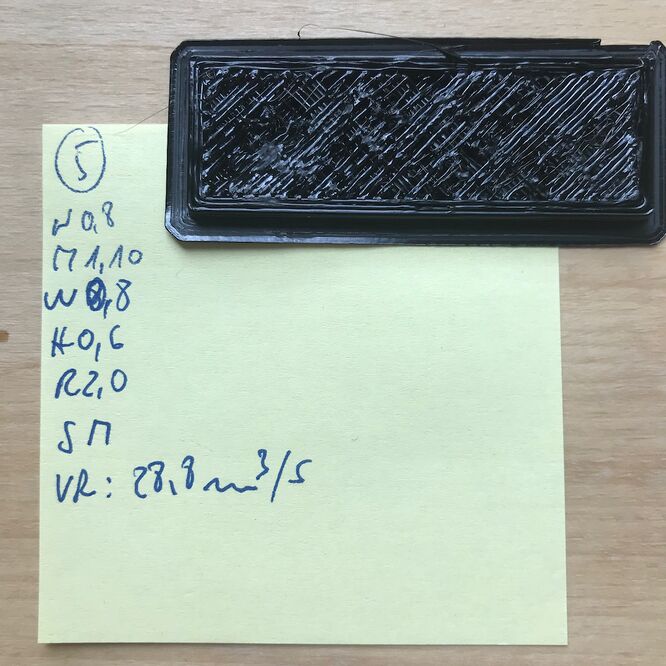

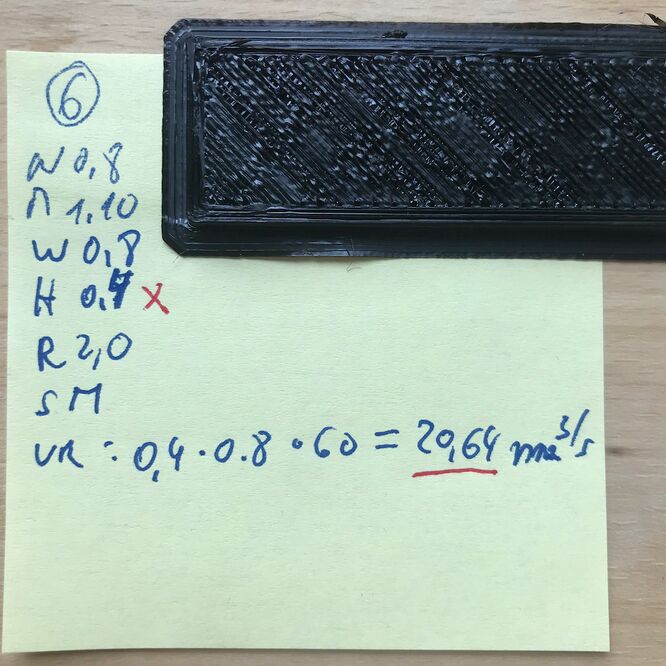

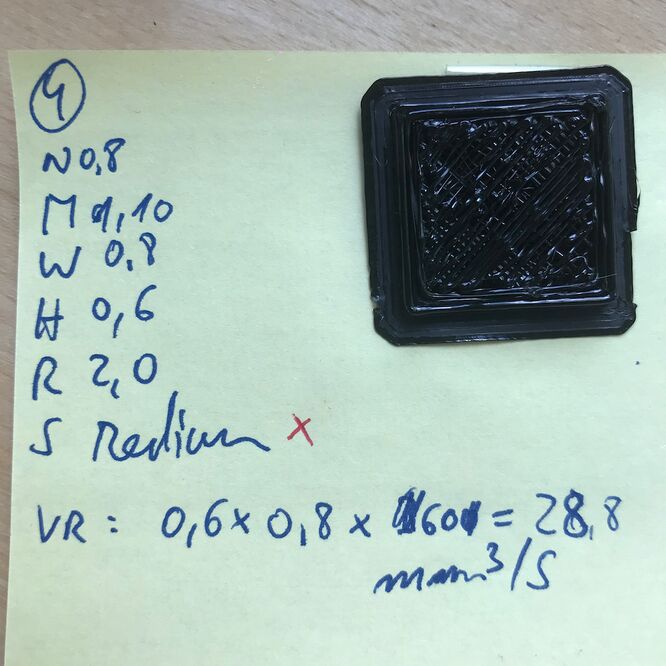

• I then calculated the volumetric rate (VR), and it was 28.8mm³/s…a bit high as it turned out…

(• and yes, I reduced speed from fast to medium in Simplify3D, but that actually didn't change anything. This preset only changes layer height, not the actual speed. And since I manually set layer height, it had no effect)

• I then calculated the volumetric rate (VR), and it was 28.8mm³/s…a bit high as it turned out…

(• and yes, I reduced speed from fast to medium in Simplify3D, but that actually didn't change anything. This preset only changes layer height, not the actual speed. And since I manually set layer height, it had no effect)

The Solution

#TLDR, Reduce volumetric rate (extruder throughput) until it looks fine :)

What's next?

- Fine-tuning the speed/VR/layer height/width…

- Toying with temperature-settings…

- 'Get a new hot-end that can handle more VR!(Probably not a good idea, the printer is old, not very precise, the controller/software is outdated, the power-supply maybe not able to handle it…(maybe a new more capable printer would be a good idea)

Lessons Learned

In general…

What the author should already have known from RFC1925(8,9) is:

- (8) It is more complicated than you think.

- (9) For all resources, whatever it is, you need more.

Printing speed

Let's think this thru. We expected that printing would be 8 times faster - did we achieve this?

- Let's assume the following:

- We're printing a simple solid object, say a cube with 10x10x10mm.

- Regardless of nozzle size, the same work has to be done. Meaning, the amount of filament used, is exactly the same.

If that's right, we can compare the printing speeds for the 0.4mm nozzle and the 0.8mm nozzle by calculating the volumetric rate (VR), right?

- 0.4mm nozzle:

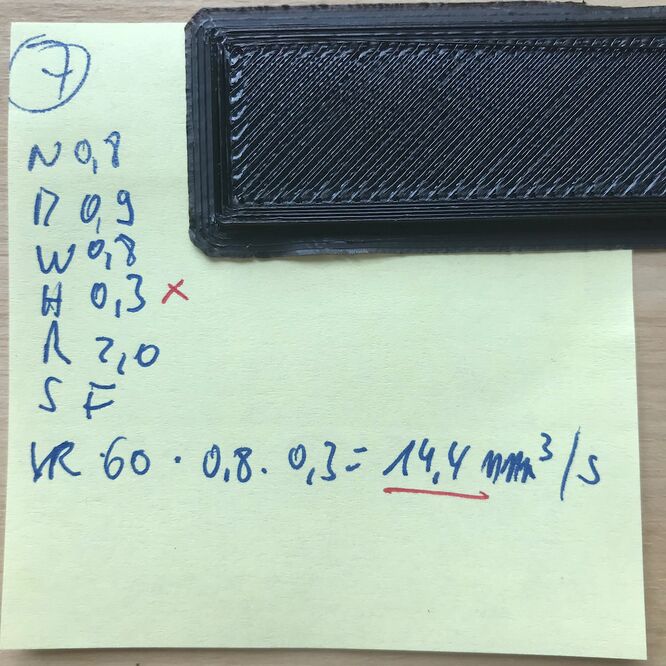

60 x 0.4 x 0.3 = 7.2mm³/s[1] - 0.8mm nozzle:

60 x 0.8 x 0.3 = 14.4mm³/s

- NARF! We only doubled the printing speed!

- Links

- https://projects.ttlexceeded.com/3dprinting_nozzle_sizes.html ← GREAT ARTICLE! Read it!

- Footnotes:

- ↑ VR = [speed in mm/s] x [layer width] x [layer height]